B.C. WATER FRACKING EXTRACTION

QUANTITY - FINALLY DEFINED

There is a high use or demand of surface

(river, stream) and

sub-surface (groundwater) water by the hydrocarbon industry in the

application

of hydraulic fracturing (“fracking”) - oil and gas well exploration.

The largest volume waste stream associated with oil and gas production is produced water. Operators in the South Midcontinent Region of the Petroleum Technology Transfer Council (PTTC) identified produced water as a major constraint in the production of hydrocarbons. The costs of lifting, separating, handling, treating, and disposing of this water are substantial. (Source: Produced Water and Associated Issues: A manual for the independent operator, by Rodney R. Reynolds, 2003)

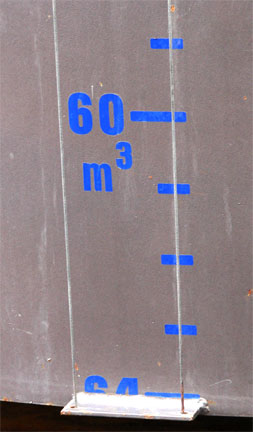

These are typical water tanks used (rented)

by the gas industry for fracking (note the man standing next to the

tank for scale). Each tank holds 64 cubic meters of water, or 14,078

imperial gallons, or 16,907 U.S. gallons. Some fracks in the Horn River

Basin may use 75 tanks, or more, for each frack.

These are typical water tanks used (rented)

by the gas industry for fracking (note the man standing next to the

tank for scale). Each tank holds 64 cubic meters of water, or 14,078

imperial gallons, or 16,907 U.S. gallons. Some fracks in the Horn River

Basin may use 75 tanks, or more, for each frack.  Below is a typical set up for multiple tank

delivery system for a fracking operation. Here about 60 tanks, holding

3,840 cubic meters (844,800 imperial gallons) of water, are connected

to a central feed line. (Operation near Farmington, southwest of

Pouce Coupe, B.C.)

Below is a typical set up for multiple tank

delivery system for a fracking operation. Here about 60 tanks, holding

3,840 cubic meters (844,800 imperial gallons) of water, are connected

to a central feed line. (Operation near Farmington, southwest of

Pouce Coupe, B.C.)

More recently, in the United States, the Susquehanna River Basin Commission notified 23 natural gas developing companies, beginning in June, 2008, that “without prior water use approval for those and other water-related activities will be considered in willful noncompliance if they continue to operate after receiving SRBC notice”, as “the Commission is exercising its regulatory authority with regard to the natural gas industry.”

Just how much water is being, or has been, used over the years in British Columbia for fracking is not known, as there is, amazingly, no administrative accounting or record-keeping for this wild, wild west practice.

The Straight article estimated that as much as 135 billion litres a year were being used for all the fracking operations in northeast BC, “enough water to fill a line of tanker trucks parked bumper to bumper around the equator - five abreast.” That’s a startling figure just for BC, never mind Alberta, the United States, or the world!

In a March 19,

2010 article by

Katarzyna Klimasinska in Houston, European

Shale-Gas Drilling Will Need More Water, Analyst Says:

“Europe has less renewable

water resources than the U.S., Sanford C. Bernstein & Co. analyst

Oswald

Clint said in a report today - “Shale-gas development in Europe using

hydraulic

fracturing will only be approved after a long debate

in Brussels, and once a

carefully structured drilling plan protecting limited existing and

future water

resources is developed,” Clint said.

The production of commercial quantities of gas from this shale requires large volumes of water to drill and hydraulically fracture the rock. This water must be recovered from the well and disposed of before the gas can flow. Concerns about the availability of water supplies needed for gas production, and questions about wastewater disposal have been raised by water-resource agencies and citizens throughout the Marcellus Shale gas development region. This Fact Sheet explains the basics of Marcellus Shale gas production, with the intent of helping the reader better understand the framework of the water-resource questions and concerns. (Source: Water Resources and Natural Gas Production from the Marcellus Shale, United Stated Geological Service)

But how accurate is this water use figure in the Straight article you might ask? The following may be reliable estimates from the industry (the horse’s mouth), which indicate that the estimate is off the mark, meaning that the annual water use figures may actually be much higher.

At the sixth annual Shale Gas Conference

recently held in  from January 26 -

27, 2010, professional geologist Ken Campbell, a

senior hydrogeologist with

Schlumberger Water Services, gave a presentation, Shale Gas Development and Water Issues in

Northeastern British Columbia. (Here's

the

background

on

Campbell

and

his

company

subsidiary:)

from January 26 -

27, 2010, professional geologist Ken Campbell, a

senior hydrogeologist with

Schlumberger Water Services, gave a presentation, Shale Gas Development and Water Issues in

Northeastern British Columbia. (Here's

the

background

on

Campbell

and

his

company

subsidiary:)

Schlumberger is

the leading

oilfield services provider for oil and gas companies around the world.

Schlumberger Water Services (SWS), a division of Schlumberger is an

international organization dedicated to groundwater management.

The company has

an array of integrated technologies and expertise for groundwater

characterization and monitoring, advanced geophysical logging, software

for

seamless integration of data, from individual tests to large scale

databases.

(Source: “Water

and Oil Do Mix!”,

by

Ken

Campbell

Schlumberger

Water

Services

paper.

It

includes

"Born and raised

in the Peace River country, Ken received his education at the

University of Alberta, and began his career in hydrogeology more than

40 years ago at the Research Council of Alberta. His subsequent career

path has included a wide variety of hydro-geologic projects, including;

groundwater supply programs, regional hydrogeological mapping, mine

dewatering, environmental impact studies, groundwater contamination

investigations and remediation. Ken’s Canadian projects have been

located in Alberta, British Columbia, Saskatchewan, Manitoba, and the

Yukon. His international experience includes projects in India,

Vietnam, Sultanate of Oman, El Salvador, Chile, Peru, and more than 150

projects in the United States.

Supplementing his project experience, Ken has participated in a variety

of groundwater-related regulatory initiatives; including the Alberta

Water For Life Initiative, Alberta Hazardous Chemical Advisory

Committee, Alberta Groundwater Allocation Policy, and participated as

Senior Scientist on the Acid Deposition Research Project." (Source:

Canadian Heavy Oil Association conference speaker biography)

- A company will make “2 - 4 fracks per day”

- For each frack there may be needed “2,000 to 4,000 cubic meters” of water

- For a one day operation of fracking of 2 to 4 fracks in a single well, there is needed 4,000 to 16,000 cubic meters of water

- For a complete frack for a well, there is needed 16,000 to 64,000 cubic meters of water

- For wells that will soon require 20 fracks, 40,000 to 80,000 cubic meters of water.

How many wells per year? 10, 25, 50, 150?

10 wells (909,090 cubic meters), 25 wells (2,272,725 cubic meters), 50 wells (4,545,450 cubic meters), 150 wells (13,636,350 cubic meters)?

It was reported on January 21, 2010 in the

Calgary Herald (Encana still high on

When Campbell’s figures are applied, per annum, to “all” the various fracking well operations in the oil and gas shale company/corporation plays in BC’s northeast, the statistics for water and toxic chemical use become quite staggering - the water of which has no cumulative recorded data by the government. In addition, no water permits, no accountability, for groundwater licensing.

What if 10 out of 15 land holders are active, and each landholder wants to frack more than one well at a time? Quickly spirals out of manageable proportions.

In pointing out these various water

resources,

All this is just for “water going in”, not the calculations for “water treatment” for water “going or coming out” of each well, and the enormous energy and requirement for this stage of the fracking game, including “water disposal” deep underground.

In

- Water needs for fracking are a significant cost component in development of shale gas in northeastern BC

- Treatment options including: Dilution, Filtration and Flocculation, Reverse Osmosis, Mechanical Vapor Recompression, Chemical and stripping options for H2S

- Disposal of water no longer needed for fracking can be effectively dealt with through injection or, some form of Aquifer Storage and Recovery - or by giving/selling to some operator in need.

HORN RIVER BASIN AQUIFER PROJECT

In late April, 2010, B.J.R. Hayes from Petrel Robertson Consulting Ltd. in Calgary published a four-page summary report for Geoscience BC, Horn River Basin Aquifer Characterization Project, Northeastern British Columbia (NTS 0941, J, O, P): Progress Report. Hayes does consulting work for the major producers in the Horn River area. The full 200-page, January 2010 report, Horn River Basin Aquifer Characterization Project - Geological Report, was scheduled to be released to the public in July, 2010, but was released on April 30, 2010. In his summary report, Hayes states that:

The petroleum industry is in its in fancy in the HRB, and so suffers from lack of well control and other information to support characterization of subsurface aquifers. While numerous wells have been drilled on the basin margins for conventional gas reservoirs, there are relatively few wells in the basin proper, and large areas remain virtually undrilled. New wells target the Devonian gas shale units, and most new geological studies have focused on their reservoir characteristics. Within the past year, however, many industry operators have begun to drill water-source and disposal wells on their properties, and are working toward understanding subsurface aquifers as potential water sources and sinks.

To determine whether subsurface aquifers have sufficient water volumes and flow capacity to support long-term development in the HRB, comprehensive regional mapping and reservoir characterization is required. The Horn River Basin Producers Group (HRBPG), a consortium of industry operators, recognized this issue in 2008, and asked Geoscience BC to undertake such a study. Geoscience BC commissioned Petrel Robertson Consulting Ltd. (PRCL) to develop a project workplan, manage the collection of test data from new HRBPG wells, undertake the required technical work, and to produce a report summarizing the findings.

Three test cases for transient well deliverability were run in order to provide ballpark estimates of pumping rates for a single well in a Debolt-Rundle aquifer. The three cases were: a high deliverability case based on a aquifer with high permeability and large total area, a low case based on an aquifer with relatively low permeability, and high deliverability case base on an aquifer with high permeability but a much smaller total area.

According to the two high cases, a single well flowing constantly for two months could produce between 200,000 and 900,000 cubic meters of water. This volume would be sufficient enough to support 15 to 50 well completions if a per completion volume of 16,000 m3 is assumed. Over a two-month period, the low-well deliverability case could not provide sufficient water for a single completion.

A single injection rate forecast was conducted for a well with relatively high permeability. At the beginning of injection, the injection rate was in excess of 10,000 m3/d but the rate drops to less than 100 m3/d in after twelve months. The cumulative volume of water injected over this twelvemonth period would be nearly 800,000 m3.

At present, companies using water for purposes of hydro-frackturing may elect to use either surface water sources such as rivers or lakes, or sub-surface (groundwater) sources.

Before using surface waters, the companies must apply either to the provincial Oil & Gas Commission (headquartered in Ft. St. John) for temporary water permits or to the provincial Ministry of Environment for a water licence.

Temporary water permits are granted under Section 8 of the Water Act. The holder of such a permit then gains access to water for a period of up to 12 months.

Currently, there are at least 252 active temporary water use permits held by companies operating in BC's northeast gas sector, with many companies holding mutiple permits. Companies holding multiple permits include: Apache Canada Ltd; Canadian Natural Resources Ltd.; Devon Canada Corp.; Imperial Oil Resources Ltd.; and Encana Corporation.

Companies may also have provisions under the Water Act for longer-term water licences. Such applications are more involved and generally require more work both by the applicant and the regulator - the Ministry of Environment. For example, the Ministry's Water Stewardship Branch is supposed to perform a technical assessment of the application to ensure that "there is sufficient water available in the source to issue a new water licence. (http://www.env.gov.bc.ca/wsd/water_rights/licence_application/index.html)

Currently, the Ministry of Environment lists 16 water licences held by companies that intend to use the water they divert for purposes of oil field injection, a category that includes hydro fracturing. Of the 16 licences held, permissions are granted to divert water from a total of 27 different points on various surface water bodies. The largest of the licences currently listed grants Nexen Inc. of Calgary four points of diversion in the in the Horn River Basin operational area. The points of diversion include the Tsea watershedTsea River, North Tsea Lake, Middle Tsea Lake and South Tsea Lake. At each site, Nexen is allowed to divert up to 1,750 cubic feet of water per second.

It is unknown how many energy companies in British Columbia may be withdrawing groundwater for purposes of hydro fracturing because BC is the only province in Canada without any general licensing requirements for groundwater extraction at any level. (Source: Out of Sight, Out of Mind? Taking Canada's Groundwater for Granted, by Linda Nowlan, in Eau Canada, Ed. Karen Bakker, UBC Press: 2007)

Regarding the issue of water use, and the operational complexities of fracking on a multi-well pad site, comes the issue of material transportation from heavy duty trucks (everything that is needed) and atmospheric pollution and green house gas emissions. Recent estimates on this concern surfaced during the New York State Department of Environment Conservation's update September 2009 draft GEIS (Generic Environmental Impact Statement) report (804 pages) on its Oil, Gas and Solution Mining Regulatory Program, regarding well permit issuance for "high-volume hydraulic fracturing". In Chapter 6, section 11, Road Use, is a statistical estimate analysis of all the truck transportation "trips" required for each fracking project. The information was obtained through a report contract by NTC Consultants, Impacts on Community Character of Horizontal Drilling and High Volume Hydraulic Fracturing in Marcellus Shale and Other Low-Permeability Gas Reservoirs (September 16, 2009). In section 6.2.1, Trucking, and 6.3., Mitigation, it states:

Drill Pad and Road Construction Equipment 10 – 45 Truckloads

Drilling Rig 30 Truckloads (double this to 60 truckloads, to complete the pad work)

Drilling Fluid and Materials 25 – 50 Truckloads (for each frack only)

Drilling Equipment (casing, drill pipe, etc.) 25 – 50 Truckloads (for each frack)

Completion Rig 15 Truckloads (double this to 30 truckloads)

Completion Fluid and Materials 10 – 20 Truckloads (for each frack)

Completion Equipment – (pipe, wellhead) 5 Truckloads (double this figure)

Hydraulic Fracture Equipment (pump trucks, tanks) 150 – 200 Truckloads (for each frack)

Hydraulic Fracture Water 400 – 600 Tanker Trucks (for each frack)

Hydraulic Fracture Sand Trucks 20 – 25 Trucks (for each frack)

Flow Back Water Removal 200 – 300 Truckloads (for each frack)

HERE'S THE MATH - Given the above scenario for a single well frack, from beginning to end of its operation, where the well has ten (10) fracks, there are a minimum of 8,510 truckloads to a maximum of 12,795 truckloads needed. (The difference in truck delivery figures has to do with the depth and overall length of drilling and fracking, which requires either more or less resources for the drilling process.) That amounts to a lot of fuel and truck emissions (great business for big oil ! ), and a lot of social disruption and environmental impact. Keep in mind there are now numerous wells per pad, some elaborate projections to include up to 24 separate drilled wells per pad.

The next step is to make a ball-park estimate of all fuel for all heavy vehicle movement from fracking operations in the United States, Canada, or the globe. That figure would help everyone to understand what the cumulative impacts have had, and will have. The other step is to estimate how much water is being used for injection purposes, and how much water is being treated in the form of a new toxic soup.

| Tap Water Alliance Home Page |

| Fracking Home Page |

| RESOURCES |

| Related Water Use Reports |

| News Stories |